Mechanical metamaterials made of freestanding quasi-bcc nanolattices of gold and copper with ultra-high energy absorption capacity

Mechanical metamaterials made of freestanding quasi-bcc nanolattices of gold and copper with ultra-high energy absorption capacity"

- Select a language for the TTS:

- UK English Female

- UK English Male

- US English Female

- US English Male

- Australian Female

- Australian Male

- Language selected: (auto detect) - EN

Play all audios:

ABSTRACT Nanolattices exhibit attractive mechanical properties such as high strength, high specific strength, and high energy absorption. However, at present, such materials cannot achieve

effective fusion of the above properties and scalable production, which hinders their applications in energy conversion and other fields. Herein, we report gold and copper quasi-body

centered cubic (quasi-BCC) nanolattices with the diameter of the nanobeams as small as 34 nm. We show that the compressive yield strengths of quasi-BCC nanolattices even exceed those of

their bulk counterparts, despite their relative densities below 0.5. Simultaneously, these quasi-BCC nanolattices exhibit ultrahigh energy absorption capacities, i.e., 100 ± 6 MJ m−3 for

gold quasi-BCC nanolattice and 110 ± 10 MJ m−3 for copper quasi-BCC nanolattice. Finite element simulations and theoretical calculations reveal that the deformation of quasi-BCC nanolattice

is dominated by nanobeam bending. And the anomalous energy absorption capacities substantially stem from the synergy of the naturally high mechanical strength and plasticity of metals, the

size reduction-induced mechanical enhancement, and the quasi-BCC nanolattice architecture. Since the sample size can be scaled up to macroscale at high efficiency and affordable cost, the

quasi-BCC nanolattices with ultrahigh energy absorption capacity reported in this work may find great potentials in heat transfer, electric conduction, catalysis applications. SIMILAR

CONTENT BEING VIEWED BY OTHERS HOLLOW MEDIUM-ENTROPY ALLOY NANOLATTICES WITH ULTRAHIGH ENERGY ABSORPTION AND RESILIENCE Article Open access 16 April 2021 CHALLENGING THE IDEAL STRENGTH LIMIT

IN SINGLE-CRYSTALLINE GOLD NANOFLAKES THROUGH PHASE ENGINEERING Article Open access 22 January 2025 METALLIC GLASS-BASED TRIBOELECTRIC NANOGENERATORS Article Open access 23 February 2023

INTRODUCTION Metamaterials are rationally structured composites, made of periodically or aperiodically organized building blocks, that manifest extreme properties and exotic functionalities

that go beyond constitutive bulk materials1. Owing to the unprecedented possibilities enabled by metamaterials, the past decade has witnessed a rapid development of functional diversity

including electromagnetic2, mechanical3,4, acoustic5, and others6,7. Among these, energy absorption mechanical metamaterials have been the subject of intense interest because they offer

exciting opportunities for highly efficient absorption of mechanical energy, which is crucial for several applications8,9,10. In principle, the ideal material for energy absorption should

concurrently possess high strength to counteract penetration and superior energy absorption capacity to withstand mechanical impact and, favorably, at low weight and/or volume. The energy

absorbed by a material is given by the integral of the plateau stress and the failure or densification strain. In most cases, unfortunately, these properties are substantially in

contradictory, i.e., high yield or fracture strength is generally gained at the price of low failure strain, and vice versa, which is well exemplified by bulk ceramics. To tackle this

problem, metamaterials have been ushered in through ingenious architectural design and material combination, leading to reasonable compromise and providing higher energy absorption

capacity11,12. For a mechanical metamaterial, its energy absorption capacity is essentially dominated by the material’s properties, including size- and microstructure-induced enhancement,

and architectural design9,13. From the perspective of material’s properties, metals possess natural high strength and high ductility and thus are unparallel candidates for the pursuit of

high energy absorption capacity. Diameter reduction, especially at the length scale below 200 nm, can bring about further mechanical enhancement, known as “smaller and stronger”14,15. The

emergence of beam structures, such as nanolattice structures, offers extensive three-dimensional configuration designability for ultra-lightweight materials with ultrahigh stiffness3,16,

large deformability and recoverability11,17,18, and ultrahigh specific strength19. Simultaneously, architectural rationalizations can endow the materials with additional enhancement and

stress platform20, which is hardly available in conventional foam materials, for instance, dealloyed nanoporous metals. Counterintuitively, recent studies have shown that, in comparison with

perfect periodical metamaterials, beam offset defects in nanolattice materials have little detriment to their stiffness and strength21. Taking these issues into consideration, it is

reasonable to speculate that higher energy absorption capacity could be pursued with nanobeams structured metals under properly designed architecture. Up till now, however, such

metamaterials have seldom been reported. Here, we demonstrate nanobeams structured mechanical metamaterials with outstanding strength and energy absorption capacity, afforded by previously

unidentified opportunities of three-dimensional (3D) nanowire networks featured with semi-order architecture composed of multi-directional parallelly orientated and randomly positioned solid

nanobeams22. In other words, we can think of this structure as a full-node-offset BCC nanolattice. For simplicity, we will refer to as quasi-BCC nanolattice. The gold and copper nanobeams

in quasi-BCC nanolattices have a dimeter down to 34 nm. Mechanical measurements demonstrate that ultrahigh energy absorption capacity up to 110 ± 10 MJ m−3 is realized with the copper

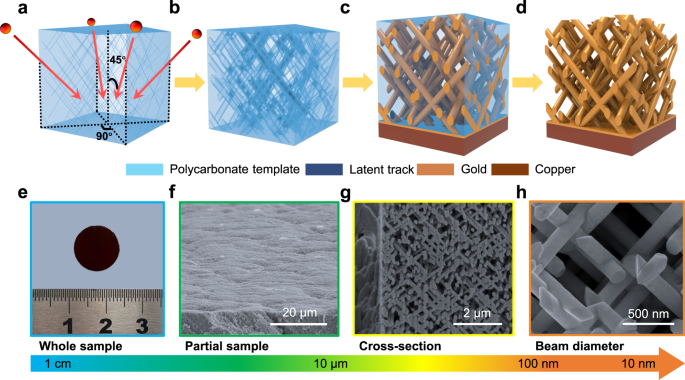

quasi-BCC nanolattice. RESULTS FABRICATION AND CHARACTERIZATION OF QUASI-BCC NANOLATTICES The gold and copper quasi-BCC nanolattices were prepared by ion track technology23, as shown in Fig.

1a–d. Firstly, a beam of swift heavy ions irradiates a piece of polycarbonate film at an angle of 45° with respect to the horizontal plane. Further irradiations can be introduced at other

directions upon demand, which is considered as an unparallel advantage of ion track technology. The passage of each ion can easily form a damaged straight path, known as ion track (Fig. 1a),

and the areal densities of ion tracks are dictated by the irradiation fluence. Then, each track is etched by chemical etching and consequently transformed into a uniform cylindrical channel

(Fig. 1b). Gold and copper quasi-BCC nanolattices are electrochemically deposited in the channels (Fig. 1c). Finally, free-standing quasi-BCC nanolattices are obtained by dissolving the

template (Fig. 1d). It is seen that the fabrication method enables an independent control over the key parameters and hence a high flexibility for tailoring quasi-BCC nanolattices, i.e., the

orientation, density, diameter, number of nanobeam bundles, and the material of interest as well. We prepared gold quasi-BCC nanolattices with beam diameters of 117 ± 5 nm, 86 ± 4 nm, 69 ±

4 nm, and 34 ± 2 nm, and the corresponding relative densities are 0.48, 0.29, 0.20, and 0.49 respectively. A copper quasi-BCC nanolattice with beam diameter of 34 ± 2 nm and a relative

density of 0.49 was also prepared using the same procedures. The main parameters of these samples are listed in Table 1. Taking the Au-117 quasi-BBC nanolattice as an example, Fig. 1e–h

shows a photograph and the structure of the as-fabricated gold quasi-BCC nanolattice. The critical feature sizes range from a dozen millimeters (whole specimen) to dozens of nanometers (beam

diameter), spanning 5 orders of magnitude of length-scale. Figure 1h shows the successful and random connection (full-node-offset) of nanobeams and each nanobeam has a straight and smooth

contour. Figure 2a–d shows the SEM morphology of gold quasi-BCC nanolattices of Au-117, Au-86, Au-69, and Au-34, and Fig. 2e is the SEM image of a copper quasi-BCC nanolattice of Cu-34.

Figure 2f is a magnified SEM image of Fig. 2e. For gold and copper quasi-BCC nanolattices with the same area density of nanobeams (7.1 × 108 × 4 cm−2) which is determined by the irradiation

fluence, as the diameter decreases, the porosity increases and the connectivity between nanobeams becomes weaker (Fig. 2a–c). In other words, good connectivity can be obtained for quasi-BCC

nanolattices with a smaller nanobeam diameter when the area density of nanobeams is higher (Fig. 2d–f). At the same area density (7.1 × 109 × 4 cm−2) and diameter, the morphologies of gold

(Fig. 2d) and copper (Fig. 2e) quasi-BCC nanolattices are almost identical, evidencing the reliability of the employed fabrication method. To examine the microstructure and the purity of our

gold and copper quasi-BCC nanolattices, we have performed characterizations of X-ray diffraction (XRD), high-resolution TEM, backscattered electron SEM, energy disperse x-ray spectra (EDS),

and electron energy loss spectroscopy (EELS). Benefiting from the above methods, we have determined that microstructures of our gold and copper quasi-BCC nanolattices are polycrystalline

and, within the detection limit of the above techniques, the nanolattices are in high purity and no impurity was detected. Details are illustrated in Supplementary Discussion 1. MECHANICAL

PROPERTIES AND MECHANISMS The mechanical properties of our quasi-BCC nanolattices were studied by compression tests. Figure 3a shows the SEM snapshots of the deformation behavior of a

representative gold quasi-BCC nanolattice sample (Au-69) under coaxial compression, at a prescribed strain rate of about 0.001 s−1. It is seen that the quasi-BCC nanolattice undergoes

progressive collapse even until 80% of compressive strain (Fig. 3a and the Supplementary Movie 1), which is in stark contrast to the instantaneous collapse observed in “perfect” periodic

nanolattices. The stress-strain curves of all samples are displayed in Fig. 3b. Generally, the mechanical response has gone through three stages, i.e., the elastic stage, the plateau stage,

and the densification stage. The compressive stiffness _E_ and compressive strength _σ_ are plotted versus the relative density \(\bar{\rho }\) in Fig. 3c, d. For gold quasi-BCC nanolattices

with the same area density (7.1 × 108 × 4 cm−2) and different beam diameters, _E_ is proportional to the 2.2 power of the relative density \(\bar{\rho }\) (Fig. 3c), it basically conforms

to the square relationship predicted by the Ashby formula1,3,10,24. Through the above relationship, it is believed that the material-dependent factor can be used to predict the compressive

stiffness of quasi-BCC nanolattices with specific relative density and area density. Compressive strength, which scales with the relative density as _σ_ ~ \(\bar{\rho }\)2.4 has been found

for different relative densities with the same area density of gold quasi-BCC nanolattices (Fig. 3d), which is quite different from the prediction of the Gibson-Ashby law with _σ_ ~

\(\bar{\rho }\)1.5. The discrepancies between _E_, _σ_, and the predictions of Ashby theory should all be greatly related to the offset nodes in the quasi-BCC nanolattice structure. The

nodal offset defect results in an increase in the power exponent, that is, a greater decrease in modulus and strength as the relative density decreases9,21. Also noteworthy is that, the

strength and the stiffness of the Au-34 quasi-BCC nanolattice can be approximately doubled compared to the Au-117 quasi-BCC nanolattice. The increase in strength can be ascribed to the size

effects, which is consistent with the previous studies9. However, the increase in stiffness is not from the size effects. Our simulations show that there is no difference in stiffness

between two samples (Supplementary Table 3). Comparing with Au-117, the increase in stiffness of Au-34 substantially stems from the difference of surface roughness between two samples. In

Supplementary Discussion 2, we illustrate that the surface roughness of the sample Au-117 is larger than that of Au-34. We also show that smaller roughness gives rise to increased stiffness.

Therefore, the increase in stiffness of Au-34 should be attributed to the reduction of surface roughness, rather than size effects. To verify the mechanical properties enabled by the

quasi-BCC nanolattices, instead of gold, we prepared a copper quasi-BCC nanolattice with the same beam dimeter of 34 nm. Because of naturally higher mechanical strength, the copper quasi-BCC

nanolattice shows stronger yield strength than gold, despite the same beam diameter of 34 nm and a relative density of 0.49. Unexpectedly, the yield strengths of both quasi-BCC nanolattices

have high values, i.e., 107 ± 11 MPa for gold and 153 ± 15 MPa for copper, and outweigh gold (100 MPa) and copper (130 MPa) bulk counterparts (Supplementary Table 1). For our 3D gold and

copper quasi-BCC nanolattices, nanobeam bending dominates the deformation behavior of this nonrigid topology5,20,25. Deformation and failure initiate at the weakest links between the longer

nanobeams with large node offset due to the locally concentrated stress applied on these nanobeams21,26. As the compression continues, the nanobeams close to the indenter continue to bend

and fail, and stress propagates to the constrained bottom region through the quasi-BCC nanolattice structure. The failure of the nanobeam continued to occur in a non-catastrophic bending

fashion and the structure continued to densify (Supplementary Movie 1). Thanks to the outstanding plasticity of metallic materials, our quasi-BCC nanolattices can withstand 80% strain

without catastrophic collapse. To gain further insights into the quasi-static compression process of the quasi-BCC nanolattices, we performed finite element simulations (Supplementary

Discussion 2) and theoretical analysis (Supplementary Discussion 3). The parameters used in the simulations are listed in Supplementary Table 2. In this work, the influence of offset nodes

in the quasi-BCC nanolattice on its mechanical properties was studied through finite element simulation (Supplementary Discussion 2). The results show that the node offset effects have a

greater impact on the mechanical properties of our quasi-BCC nanolattices, as comparing with those on the reported octet-truss nanolattices21. Moreover, additional simulations have been

performed to illustrate the effects of contact state and surface roughness on the stiffness and the strength (Supplementary Discussion 2). We find that the contact state and surface

roughness have obvious impacts on the stiffness and a limited influence on the strength. We also show that the compressive strength of a quasi-BCC nanolattice can be well calculated by an

equation (Supplementary Discussion 3 and Supplementary Table 4). The absorbed energy of a material, _U_, is the strain energy, defined as the integral of the corresponding stress-strain

response, that is, the area under the stress-strain curve8: $${U}=\int _{0}^{{\varepsilon }_{D}}\sigma (\varepsilon )d\varepsilon$$ (1) where _ε__D_ is the densification strain. The energy

absorption value is a unit volume parameter independent of the nanolattice size. Compared to previous micro/nanolattices, our gold and copper quasi-BCC nanolattices exhibit higher energy

absorption capacity (Fig. 4)13,16,17,18,19,27,28,29,30,31,32,33. Although ceramics and carbon nanolattices have high strength and rigidity, they tend to collapse and lose their mechanical

properties destructively under a small strain, thus cannot achieve continuous energy absorption, resulting in moderate energy absorption capacity. On the other hand, metallic nanolattices

usually have a high non-destructive strain when subjected to force, so that they continuously absorb energy during the deformation process, but the problem is that the current hollow beam

metallic nanolattices generally have low strength, which limits their energy absorption capacity. In contrast to hollow beam, our gold and copper quasi-BCC nanolattices consist of nano-sized

solid beams and hence exhibit large continuous strains and high compressive strengths when compressed, rendering a high energy absorption per unit volume (up to 100 ± 6 MJ m−3 for gold

quasi-BCC nanolattice and up to 110 ± 10 MJ m−3 for copper quasi-BCC nanolattice), surpassing most micro/nanolattices, while being 1–3 orders of magnitude larger than those of natural porous

materials with comparable densities. In addition, the copper quasi-BCC nanolattice can achieve an energy absorption per unit mass of 20 J g−1, which is commendable for metals with high

densities. Such excellent mechanical properties and energy absorption capabilities make gold and copper quasi-BCC nanolattices having great advantages and potential in future multifunctional

applications. EXTENDIBILITY OF THE FABRICATION METHOD Macroscopic size is essential for the implementation of metamaterials in future applications. From this perspective, our ion track

technology-based fabrication method can generate macroscale flat quasi-BCC nanolattices with high efficiency, compared to previous methods based on 3D printing and self-assembly34,35,36. In

contrast to the large lateral size of the quasi-BCC nanolattices, the state-of-art maximum thickness of ion track template is 100 μm which is significantly lower than the centimeter scale

thickness fabricated by the self-propagating polymer waveguide technology37. In addition, the lower limit of the relative density is estimated through geometric models and finite element

simulations in combination with experimental test (Supplementary Discussion 4). With the aid of geometric models and finite element simulations, we show the lower limit of the relative

density of our quasi-BCC nanolattices can be as low as 0.01. However, because of the morphological damage induced by the surface tension of dichloromethane during dissolving polycarbonate

template, the experimental test shows that the quasi-BCC nanolattice with a relative density of 0.15 starts to lose its structural integrity partially. With the guidance of the geometric

model analysis and finite element simulation, it is reasonable to anticipate the quasi-BCC nanolattices with the relative densities lower than 0.2 could be experimentally fabricated by

further refining the experimental process. DISCUSSION We provide an in-depth exploration of mechanical gold and copper quasi-BCC nanolattices using experiments, theoretical calculation, and

finite element analysis. Our work establishes that gold and copper quasi-BCC nanolattices have excellent compressive strength and energy absorption capacity, which substantially result from

the synergy of the naturally high mechanical strength and plasticity of metals, the relevant size reduction-induced mechanical enhancement, and the quasi-BCC nanolattice architecture. We

demonstrate that, despite imperfect periodicity, the gold and copper quasi-BCC nanolattices remain slightly lower yet comparable mechanical strength and energy absorption capacity as

comparing with perfect nanolattice of similar feature size and relative density. Such a defect-tolerant behavior may promise scalable fabrication methods eligible for future real

applications, though structural imperfections are inevitably introduced in the metamaterials. We hope that this work provides some hints for the further design and fabrication of lightweight

porous metals with high strength, energy absorption, electrical, and thermal conductivity, and thereby offer promising prospects for realizing high-performance multifunctional applications.

METHODS PREPARATION The gold and copper quasi-BCC nanolattices were prepared by electrochemical deposition in the channels of heavy ion track templates. First, the polycarbonate (PC) foils

were irradiated by swift heavy ions at the Heavy Ion Research Facility at Lanzhou (HIRFL) with 9.5 MeV per nucleon 209Bi ions. The thickness of the templates was 30 µm and the fluence of

irradiation was 7.1 × 108 or 7.1 × 109 cm−2 in four directions. Following that, each side of the template was illuminated with UV light for 2 h. The purpose of this step was to make the

track etching rate of the template much larger than the bulk etching rate during the etching process, to ensure the uniform channel after etched. Then, the template was placed in 50 °C, 5 M

NaOH solution and etched for a certain time to obtain the template with a certain aperture channel. After that, the etched template was rinsed several times in deionized water immediately

and then immersed in deionized water for 5 minutes to remove the remaining etchant from the template to avoid over-etching. A thin layer of gold was sputtered on one template side as an

electrochemically deposited cathode and a layer of copper was deposited on the same side to increase the strength of the template using electrolyte consisting of 75 g L−1 CuSO4⋅5H2O and 30 g

L−1 H2SO4. The electrolyte used for gold and copper quasi-BCC nanolattices deposition on the other side were 75 g L−1 Na3Au(SO3)2 or 75 g L−1 CuSO4⋅5H2O and 30 g L−1 H2SO4 solution. Last,

the PC templates with quasi-BCC nanolattices was placed in dichloromethane (CH2Cl2) solution to dissolve organic components to obtain gold and copper quasi-BCC nanolattices. All the

quasi-BCC nanolattices were stored in ethanol. The PC template obtained by chemical etching and the electrochemically deposited quasi-BCC nanolattice structure were complementary structures.

By weighing out the PC template before and after chemical etching, the relative density of the prepared gold and copper quasi-BCC nanolattice was given by formula (2)38: $$\bar{{\rho

}}=\frac{V-{V}_{e}}{V}=\frac{M-{M}_{e}}{M}$$ (2) where _V_ is the overall volume of the template before etching; _V_e is the volume of the template after etching; _M_ is the overall mass of

the template before etching; _M_e is the mass of the template after etching. MORPHOLOGICAL AND CHEMICAL CHARACTERIZATION The morphology and crystallinity of gold and copper quasi-BCC

nanolattices were analyzed by XRD (Rigaku D/MAX2200pc, Cu K_α_ radiation, _λ_ = 1.54 Å), scanning electron microscopy (SEM, FEI NanoSEM 450, acceleration voltage 15 kV), and transmission

electron microscopy (TEM, FEI Tecnai G2 F20, acceleration voltage 200 kV). FOCUSED ION BEAM The mechanical samples were obtained by cutting centimeter-scale quasi-BCC nanolattices with a

focused ion beam system (FIB, FEI, Helios NanoLab 600i). The gold and copper quasi-BCC nanolattices were first pre-cut with a Ga ion beam current of 65 nA at a vacuum of 10−6 Pa. The

micropillars were then finely cut into cubes of approximately 10 × 10 × 10 µm3 with a Ga ion beam current of 2.5 nA. MECHANICAL CHARACTERIZATION In situ nanocompression testing in SEM (Zeiss

Auriga) was performed using a PI 88 (Hysitron) system with a flat indenter (~20 μm diameter). The sample platform was tilted 15° to view live compressed images. The displacement control

mode was applied to the micropillar compression with a loading rate of 10 nm s−1. The compressive strength _σ_ of the structure was defined as the stress at which the structure yields, and

the Young’s modulus _E_ was determined as the maximum slope of the corresponding stress-strain curve. The densification strains were determined according to Ref. 39, that is, the

corresponding strain when the stress rises steeply39. At least three micropillars were selected for each sample for repeated compression tests. SIMULATION Nonlinear simulations were

performed for compressive properties of the gold quasi-BCC nanolattices using the explicit solver of the commercial software Abaqus. The Monte Carlo technique was adopted to simulate planar

distribution of ion tracks, i.e., the _X_ and _Y_ coordinates of each ion track are generated by a random number generator40. In building a simulation model, a tilted beam was placed at the

generated _X_ and _Y_ coordinates of each ion track and ultimately formed a 3D quasi-BCC model. Due to limited computational resources, the volumes of models in finite element simulations

are 1 × 1 × 1 μm3 for the area density of 7.1 × 108 × 4 cm−2 and 0.3 × 0.3 × 0.3 μm3 for the area density of 7.1 × 109 × 4 cm−2. The relative density difference between the established model

and the actual sample was less than 5%. The models were divided into tetrahedral meshes by hyper mesh software, and then imported into Abaqus finite element simulation software for

simulation, the ratio of kinetic energy to internal energy must be less than 5% throughout the simulation to ensure quasi-static compression. All nanobeams were rigidly connected, the bottom

nodes had zero degrees of freedom in the horizontal and vertical directions, and the top nodes were in contact with the rigid body indenter. The contact attribute of the whole model during

compression was set to “all with self”, hard contact and separation after contact was allowed. Use the quality scaling feature in the software to ensure the reliability and accuracy of

finite element simulations, while increasing simulation speed and saving time. REPORTING SUMMARY Further information on research design is available in the Nature Portfolio Reporting Summary

linked to this article. DATA AVAILABILITY The raw data that support the results of this study are available in the source data. The source data used in this study are also available in the

Science Data Bank database (https://www.scidb.cn/en/detail?dataSetId=ce57ed50bfa44d1d99adc2cceb404bf9). Source data are provided with this paper. REFERENCES * Kadic, M., Milton, G. W., van

Hecke, M. & Wegener, M. 3D metamaterials. _Nat. Rev. Phys._ 1, 198–210 (2019). Article Google Scholar * Schurig, D. et al. Metamaterial electromagnetic cloak at microwave frequencies.

_Science_ 314, 977–980 (2006). Article ADS MathSciNet CAS PubMed Google Scholar * Schaedler, T. A. et al. Ultralight metallic microlattices. _Science_ 334, 962–965 (2011). Article ADS

CAS PubMed Google Scholar * Lakes, R. Foam structures with a negative poisson’s ratio. _Science_ 235, 1038–1040 (1987). Article ADS CAS PubMed Google Scholar * Cai, L.-W. &

Sánchez-Dehesa, J. Analysis of cummer–schurig acoustic cloaking. _N. J. Phys._ 9, 450 (2007). Article Google Scholar * Veselago, V. G. Electrodynamics of substances with simultaneously

negative ϵ and μ. _Usp. Fiz. Nauk_ 92, 517 (1967). Article CAS Google Scholar * Shelby, R. A., Smith, D. R. & Schultz, S. Experimental verification of a negative index of refraction.

_Science_ 292, 77–79 (2001). Article ADS CAS PubMed Google Scholar * Lu, G. & Yu, T X. Energy absorption of structures and materials. (Elsevier, 2003) * Bauer, J. et al.

Nanolattices: An emerging class of mechanical metamaterials. _Adv. Mater._ 29, 1701850 (2017). Article Google Scholar * Gibson, L. J. Cellular solids. _MRS Bull._ 28, 270–274 (2003).

Article Google Scholar * Surjadi, J. U. et al. Hollow medium-entropy alloy nanolattices with ultrahigh energy absorption and resilience. _NPG Asia Mater._ 13, 1–7 (2021). Article Google

Scholar * Feng, X. et al. Microalloyed medium-entropy alloy (MEA) composite nanolattices with ultrahigh toughness and cyclability. _Mater. Today_ 42, 10–16 (2021). Article CAS Google

Scholar * Zhang, X., Wang, Y., Ding, B. & Li, X. Design, fabrication, and mechanics of 3D micro‐/nanolattices. _Small_ 16, 1902842 (2020). Article CAS Google Scholar * Li, X. &

Gao, H. Smaller and stronger. _Nat. Mater._ 15, 373–374 (2016). Article ADS CAS PubMed Google Scholar * Jin, H. J., Weissmüller, J. & Farkas, D. Mechanical response of nanoporous

metals: A story of size, surface stress, and severed struts. _MRS Bull._ 43, 35–42 (2018). Article ADS Google Scholar * Zheng, X. et al. Ultralight, ultrastiff mechanical metamaterials.

_Science_ 344, 1373–1377 (2014). Article ADS CAS PubMed Google Scholar * Meza, L. R., Das, S. & Greer, J. R. Strong, lightweight, and recoverable three-dimensional ceramic

nanolattices. _Science_ 345, 1322–1326 (2014). Article ADS CAS PubMed Google Scholar * Zhang, X. et al. Three-dimensional high-entropy alloy–polymer composite nanolattices that overcome

the strength–recoverability trade-off. _Nano Lett._ 18, 4247–4256 (2018). Article ADS CAS PubMed Google Scholar * Bauer, J., Schroer, A., Schwaiger, R. & Kraft, O. Approaching

theoretical strength in glassy carbon nanolattices. _Nat. Mater._ 15, 438–443 (2016). Article ADS CAS PubMed Google Scholar * Deshpande, V., Ashby, M. & Fleck, N. Foam topology:

Bending versus stretching dominated architectures. _Acta. Mater._ 49, 1035–1040 (2001). Article ADS CAS Google Scholar * Meza, L. R. et al. Reexamining the mechanical property space of

three-dimensional lattice architectures. _Acta. Mater._ 140, 424–432 (2017). Article ADS CAS Google Scholar * Rauber, M. et al. Highly-ordered supportless three-dimensional nanowire

networks with tunable complexity and interwire connectivity for device integration. _Nano Lett._ 11, 2304–2310 (2011). Article ADS CAS PubMed Google Scholar * Fischer, B. E. &

Spohr, R. Production and use of nuclear tracks: Imprinting structure on solids. _Rev. Mod. Phys._ 55, 907 (1983). Article ADS CAS Google Scholar * Ashby, M. F. & Medalist, R. The

mechanical properties of cellular solids. _Metall. Trans. A_ 14, 1755–1769 (1983). Article Google Scholar * Deshpande, V. S., Fleck, N. A. & Ashby, M. F. Effective properties of the

octet-truss lattice material. _J. Mech. Phys. Solids_ 49, 1747–1769 (2001). Article ADS CAS MATH Google Scholar * Vangelatos, Z. et al. Strength through defects: A novel bayesian

approach for the optimization of architected materials. _Sci. Adv._ 7, eabk2218 (2021). Article ADS PubMed PubMed Central Google Scholar * Zheng, X. et al. Multiscale metallic

metamaterials. _Nat. Mater._ 15, 1100–1106 (2016). Article ADS CAS PubMed Google Scholar * Mieszala, M. et al. Micromechanics of amorphous metal/polymer hybrid structures with 3D

cellular architectures: size effects, buckling behavior, and energy absorption capability. _Small_ 13, 1602514 (2017). Article Google Scholar * Gu, X. W. & Greer, J. R. Ultra-strong

architected Cu meso-lattices. _Extrem. Mech. Lett._ 2, 7–14 (2015). Article ADS Google Scholar * Bonatti, C. & Mohr, D. Smooth-shell metamaterials of cubic symmetry: Anisotropic

elasticity, yield strength and specific energy absorption. _Acta Mater._ 164, 301–321 (2019). Article ADS CAS Google Scholar * Tancogne‐Dejean, T., Diamantopoulou, M., Gorji, M. B.,

Bonatti, C. & Mohr, D. 3D plate‐lattices: An emerging class of low‐density metamaterial exhibiting optimal isotropic stiffness. _Adv. Mater._ 30, 1803334 (2018). Article Google Scholar

* Bonatti, C. & Mohr, D. Large deformation response of additively-manufactured FCC metamaterials: From octet truss lattices towards continuous shell mesostructures. _Int. J. Plast._

92, 122–147 (2017). Article Google Scholar * Bauer, J., Hengsbach, S., Tesari, I., Schwaiger, R. & Kraft, O. High-strength cellular ceramic composites with 3D microarchitecture. _Proc.

Natl, Acad. Sci._ 111, 2453–2458 (2014). Article ADS CAS PubMed Google Scholar * Duan, J. L. et al. Vertically-aligned single-crystal nanocone arrays: Controlled fabrication and

enhanced field emission. _ACS Appl. Mater. Inter._ 8, 472–479 (2016). Article CAS Google Scholar * Duan, J. L. et al. Controlled synthesis and diameter-dependent optical properties of Cu

nanowire arrays. _Mater. Sci. Eng. B_ 147, 57–62 (2008). Article CAS Google Scholar * Liu, J. et al. Electrochemical fabrication of single-crystalline and polycrystalline Au nanowires:

the influence of deposition parameters. _Nanotechnology_ 17, 1922 (2006). Article ADS CAS Google Scholar * Toimil-Molares, M. E. Characterization and properties of micro-and nanowires of

controlled size, composition, and geometry fabricated by electrodeposition and ion-track technology. _Beilstein J. Nanotech._ 3, 860–883 (2012). Article Google Scholar * Sertova, N.,

Balanzat, E., Toulemonde, M. & Trautmann, C. Investigation of initial stage of chemical etching of ion tracks in polycarbonate. _Nucl. Instrum. Meth. B_ 267, 1039–1044 (2009). Article

ADS CAS Google Scholar * Ashby, M. F. The properties of foams and lattices. _Philos. T. R. Soc. A_ 364, 15–30 (2006). Article ADS MathSciNet CAS Google Scholar * Li, B. et al.

Foreseeing two dimensional distribution of swift heavy ions at micro-scale. _Nucl. Phys. Rev._ 39, 245–251 (2022). MathSciNet Google Scholar Download references ACKNOWLEDGEMENTS This work

was supported by the National Natural Science Foundation of China (Grant No. U1932210, H.C., J.D.) and the Key Research Program of Frontier Sciences, CAS (Grant No. QYZDB-SSW-SLH010, H.C.,

J.D.). The authors thank the HIRFL staff and Prof. Weiqing Yang and Prof. Youmei Sun for providing ion beams and the assistance with the simulations, Prof. Zhi Qin’s group for performing the

XRD characterization, and Prof. Yong Peng’s group for the assistance with the EELS measurement. AUTHOR INFORMATION AUTHORS AND AFFILIATIONS * Institute of Modern Physics, Chinese Academy of

Sciences, Lanzhou, 730000, China Hongwei Cheng, Xiaoxia Zhu, Jie Liu, Huijun Yao & Jinglai Duan * School of Nuclear Science and Technology, University of Chinese Academy of Sciences,

Beijing, 100049, China Hongwei Cheng, Xiaoxia Zhu, Jie Liu, Huijun Yao & Jinglai Duan * International Joint Laboratory for Light Alloys (MOE), College of Materials Science and

Engineering, Chongqing University, Chongqing, 400045, China Xiaowei Cheng, Pengzhan Cai & Ling Zhang * Advanced Energy Science and Technology Guangdong Laboratory, Huizhou, 516000, China

Jinglai Duan Authors * Hongwei Cheng View author publications You can also search for this author inPubMed Google Scholar * Xiaoxia Zhu View author publications You can also search for this

author inPubMed Google Scholar * Xiaowei Cheng View author publications You can also search for this author inPubMed Google Scholar * Pengzhan Cai View author publications You can also

search for this author inPubMed Google Scholar * Jie Liu View author publications You can also search for this author inPubMed Google Scholar * Huijun Yao View author publications You can

also search for this author inPubMed Google Scholar * Ling Zhang View author publications You can also search for this author inPubMed Google Scholar * Jinglai Duan View author publications

You can also search for this author inPubMed Google Scholar CONTRIBUTIONS J.D. conceived the idea. H.C. and J.D. designed the experiments. H.C. have performed various tasks including

membrane sample preparation, characterization, performance testing, and finite element simulations. H.C., X.Z., H.Y., J.L., and J.D. irradiated samples. X.Z. was involved in transmission

electron microscopy characterization. L.Z., X.C., and P.C. performed in situ mechanical property tests. All authors discussed the results. H.C., X.Z., L.Z., and J.D. contributed to the

writing and revision of the manuscript. CORRESPONDING AUTHORS Correspondence to Ling Zhang or Jinglai Duan. ETHICS DECLARATIONS COMPETING INTERESTS The authors declare no competing

interests. PEER REVIEW PEER REVIEW INFORMATION _Nature Communications_ thanks the anonymous reviewers for their contribution to the peer review of this work. Peer reviewer reports are

available. ADDITIONAL INFORMATION PUBLISHER’S NOTE Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations. SUPPLEMENTARY

INFORMATION SUPPLEMENTARY INFORMATION PEER REVIEW FILE DESCRIPTION OF ADDITIONAL SUPPLEMENTARY FILES SUPPLEMENTARY MOVIE 1 REPORTING SUMMARY SOURCE DATA SOURCE DATA RIGHTS AND PERMISSIONS

OPEN ACCESS This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or

format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or

other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in

the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the

copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/. Reprints and permissions ABOUT THIS ARTICLE CITE THIS ARTICLE Cheng, H., Zhu, X., Cheng,

X. _et al._ Mechanical metamaterials made of freestanding quasi-BCC nanolattices of gold and copper with ultra-high energy absorption capacity. _Nat Commun_ 14, 1243 (2023).

https://doi.org/10.1038/s41467-023-36965-4 Download citation * Received: 03 August 2022 * Accepted: 16 February 2023 * Published: 04 March 2023 * DOI:

https://doi.org/10.1038/s41467-023-36965-4 SHARE THIS ARTICLE Anyone you share the following link with will be able to read this content: Get shareable link Sorry, a shareable link is not

currently available for this article. Copy to clipboard Provided by the Springer Nature SharedIt content-sharing initiative

Trending News

Do I Get Social Security Survivor Benefits?0:44 Videos de AARP Do I Get Social Security Survivor Benefits? Facebook Twitter LinkedIn The requirements for Social Se...

Comment: insulation for the nationBut many of those from sustainable living expert Julia Goodfellow-Smith are ingenious, such as using radiator reflectors...

Some states tax your social security benefitsMINNESOTA For 2024, Minnesotans with AGIs of up to $82,190 for an individual and up to $105,380 for a couple filing join...

Search for girl moves to mountain cabinRIVERSIDE — Detectives on Friday searched a mountain cabin belonging to relatives of a San Bernardino police officer who...

Princess kate beating sussexes at american game with break from diana mouldSchofield noted that while Kate is more quiet whereas Diana was outspoken in her support for key causes, the pair share ...

Latests News

Mechanical metamaterials made of freestanding quasi-bcc nanolattices of gold and copper with ultra-high energy absorption capacityABSTRACT Nanolattices exhibit attractive mechanical properties such as high strength, high specific strength, and high e...

Kcet 2022: application window reopens on may 29, here's how to fill registration formKCET Application 2022: The Karnataka Examinations Authority is scheduled to reopen Karnataka Common Entrance Test 2022 r...

Inequality in high-cost borrowing and unemployment insurance generosity in us states during the covid-19 pandemicABSTRACT US consumers may turn to the private market for credit when income and government benefits fall short. The most...

Dwp wrongly chased mum and aspiring nurse for money – now they are deadTWO WOMEN IN GREATER MANCHESTER WERE HOUNDED BY THE DWP OVER SUPPOSED DEBTS WHICH LED TO THEM LOSING THEIR HOUSING BENEF...

The page you were looking for doesn't exist.You may have mistyped the address or the page may have moved.By proceeding, you agree to our Terms & Conditions and our ...